h2-globe

ABOUT US

H2-GLOBE is a Green Tech company based in the USA, Canada, and Germany, committed to setting new global standards as pioneers in Green Technologies. Our installations are not only emissions-free but also known for their ease of installation and operation, suitability for extreme weather conditions, exceptional reliability, and durability.

As a Climate Tech Firm with operations in Canada, the United States, and the European Union, we exclusively leverage our proprietary IP-protected Patented Technologies for CO2 capture and conversion, transforming CO2 into blue hydrogen and blue methanol.

Technological Advantages

H2-Globe Matrix Conversion System stands as a pinnacle of innovation, characterized by its remarkably compact unit design

Compact Unit Design:

Our system is engineered to occupy minimal space while delivering maximum efficiency.

Enhanced Productivity:

The system boasts significantly higher productivity rates when

compared to state-of-the-art processes, making it a leader in output efficiency.

Energy-Efficient Operation:

Operating with exceptional energy efficiency, our system runs at lower temperatures and achieves autothermal (energy-neutral) reactions.

Minimal Material Requirements:

The low-temperature process necessitates fewer material resources, contributing to sustainability and cost-effectiveness.

Versatile Gas Utilization:

It can effectively utilize various types of hydrocarbon gases, offering versatility and adaptability in fuel sources.

Modularity and Mobility:

Designed with modularity in mind, our system allows for

flexible, mobile solutions that can be easily integrated into diverse operational contexts.

Reduced Steam Consumption:

It utilizes significantly less steam, reducing resource

consumption by a factor of three compared to conventional methods.

Lower Power Demands:

The system’s efficiency is reflected in its lower power

requirements, reducing operational costs and environmental impact.

1. No External Heat Sources Needed: It operates without requiring external heat sources, making it autothermal.

2. Compact Design:

The autothermal conversion process takes place in a single device, ensuring compactness.

3. Lower Operating Temperatures:

Unlike traditional autothermal reforming plants, this innovative method operates at reduced temperatures. This minimizes demands on reactor manufacturing materials and specifications for catalytic pipes.

4. Simplified Startup and Shutdown:

Starting and stopping the installation is easier compared to steam reforming furnaces. There is no need for complex heat exchange equipment like heat recovery boilers, and emissions of combustion products into the atmosphere are eliminated.

5. Suitable for Small and Remote Fields:

It enables low-capacity installations to process associated gases in small and remote gas and oil fields.

6. Variable Performance:

The reactor’s performance can be adjusted within a wide range of values (70% – 120% of rated power).

7. No Pre-Reforming Required:

The processing of hydrocarbon gases does not necessitate a pre-reforming stage.

8. Simultaneous or Separate Production:

It can produce hydrogen and methanol simultaneously or separately.

9. Zero Carbon Emissions: Production of blue methanol does not emit carbon dioxide into the atmosphere.

10. High Heat Release:

It releases a substantial amount of heat that can be used for heating or electricity generation.

11. High Productivity:

It boasts high specific productivity, being 10-20 times more efficient than steam conversion.

12. No Partial Oxidation Catalysts:

There is no need for partial oxidation catalysts, significantly reducing purification and preparation costs for hydrocarbon gas. 13. Versatile Feedstock: Initial hydrocarbon gases can have varying compositions, such as natural gas, associated petroleum gas, ethane, or biogas. 14. CO2 Utilization: It utilizes CO2 in the process while producing blue methanol.

Producing green hydrogen with practically zero or negative cost

H2-GLOBE’s technology allows us to produce green methanol or green hydrogen at practically zero or negative cost.

This maximizes benefits and allows us to convert practically any biomass into clean green methanol and green hydrogen. Since our production is not dependent on the feedstock’s quality, we can engage local farmers in cultivating crops like energy grass. This initiative will create numerous jobs for both farmers and technologists involved in building and operating green hydrogen and green methanol facilities.

Being categorized as Green Methanol and Green Hydrogen Producers is essential to us, as it makes H2-GLOBE eligible for various subsidies and grants from the Canadian and US governments. Energy grass cultivation does not require fertile land; it can thrive on contaminated or arid land.

H2-GLOBE notable financial advantage of processing energy grass into Green Methanol and Green Hydrogen is the ability to offset feedstock costs by selling residual biomass as livestock feed. This sustainable approach not only enhances cost-effectiveness but also aligns with our commitment to environmental responsibility.

For instance, we can grow up to 1,000,000 tons of energy grass annually on 55,000 acres of land. Moreover, for every 1 kg of green hydrogen/blue methanol produced, we generate 3 kg of high-quality animal food that can offet expences for the cost of the feedstock and OPEX

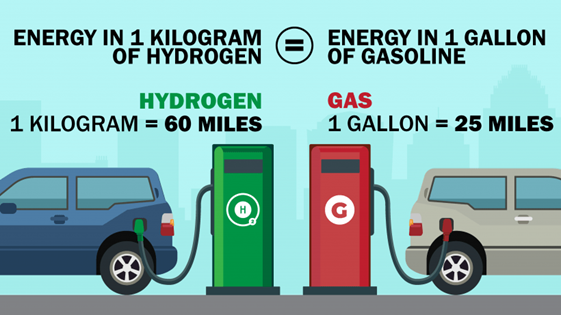

High-Efficient Storage of Hydrogen at low Pressure

Innovative H2 storage by using Iron-oxide

Storage and transportation cost reduction by factor >2

Container Module for Hydrogen storage using iron-oxide technology